JOIN

Join the Manufacturing Revolution

the Manufacturing Revolution

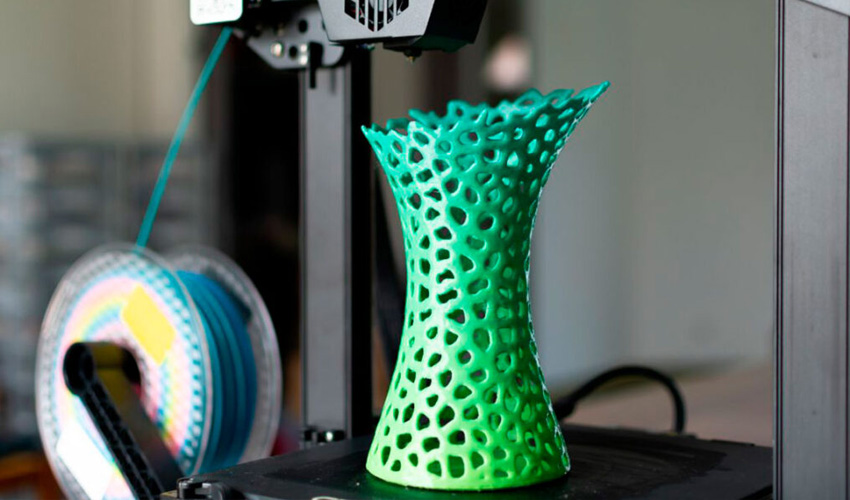

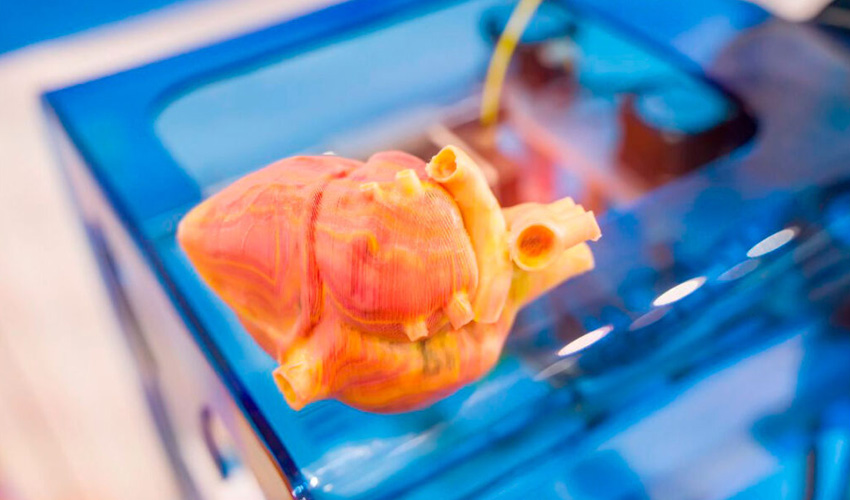

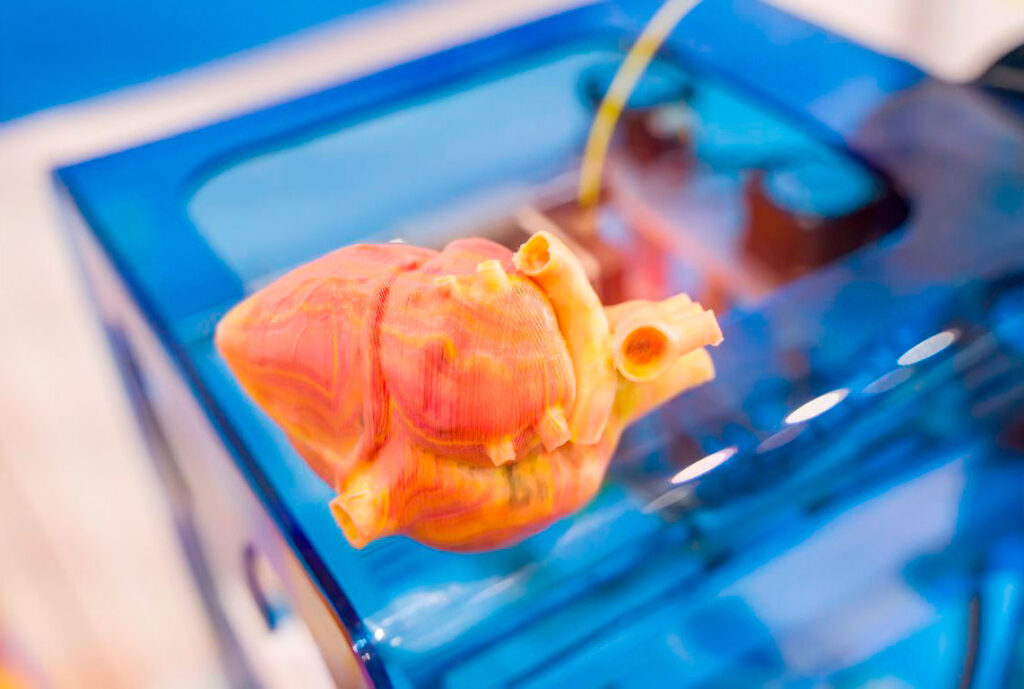

Ryoga Engineering offers 3D printing, low to high volume additive manufacturing, 3D design and reverse engineering services to companies of all industries and sizes for medical, consumer, electronics, automotive, aerospace, industrial, sports and more.

Ryoga Engineering’s 3D printing and additive manufacturing services are ideal for accelerating product development and production processes. Ryoga can accelerate your product development process from design to prototyping and manufacturing in a highly efficient and rapid manner.

Our manufacturing team is ready to meet your needs with a wide range of processes and materials.

What is additive and what are its advantages

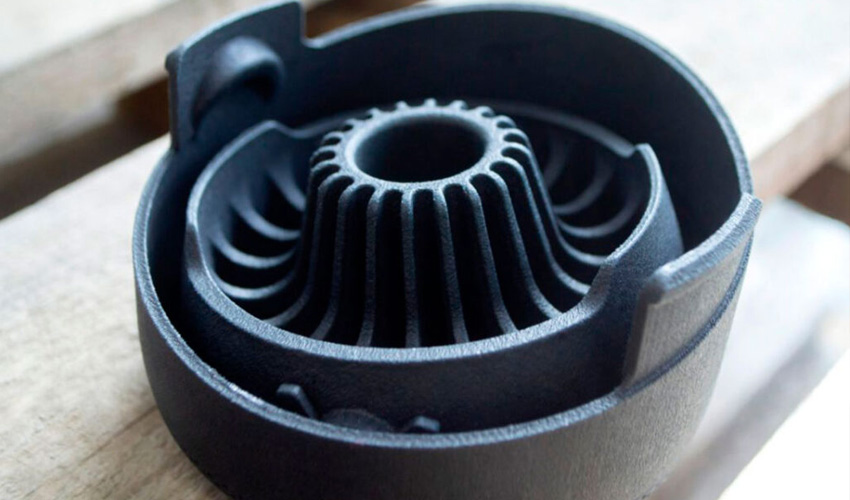

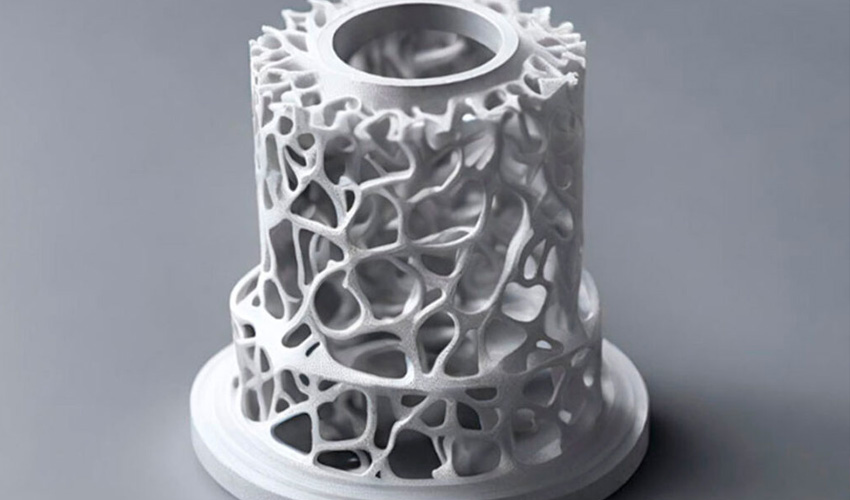

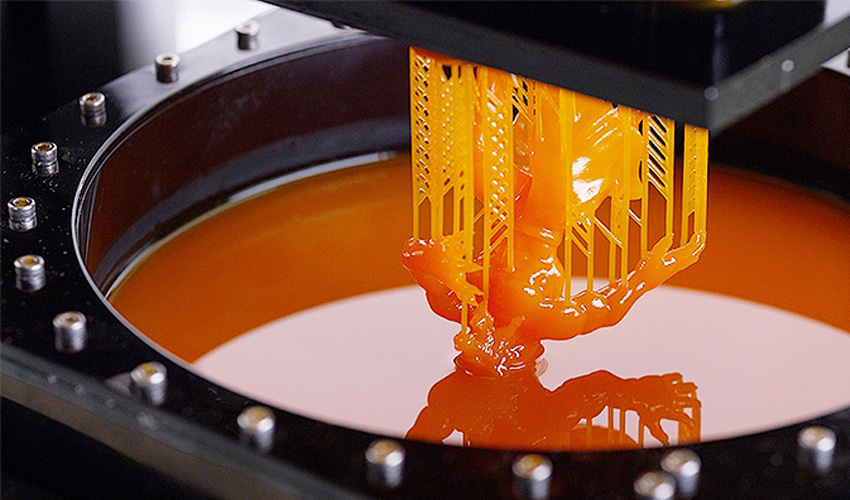

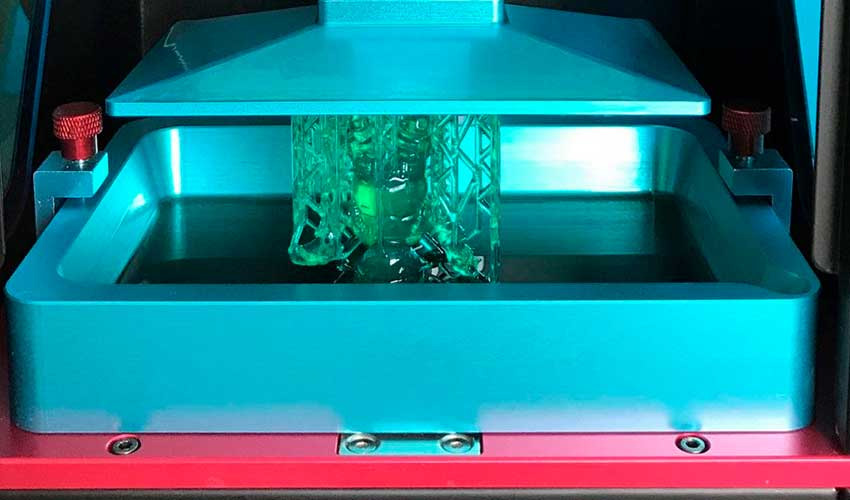

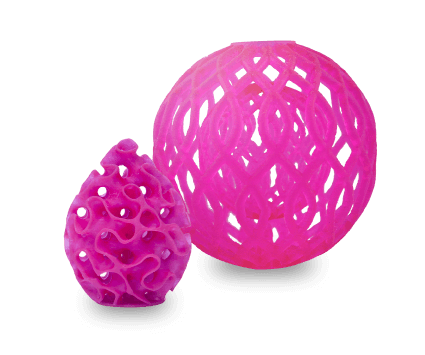

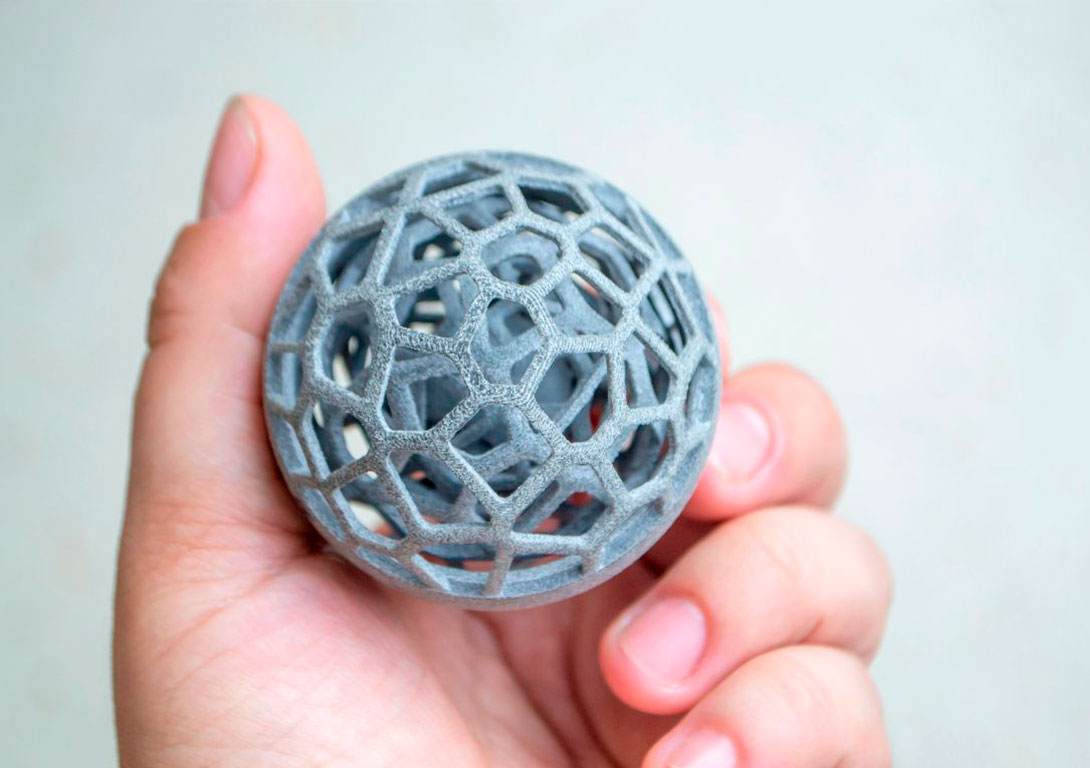

Additive manufacturing, or layered additive manufacturing, uses computer-aided design (CAD) or a 3D model to instruct machines to build an object layer by layer. The CAD drawing acts as a set of instructions or blueprints that illustrate all the intricacies of the product to be manufactured. These drawings tell the machine where and when to place the material. In this way, complex objects can be manufactured without the need to assemble separate parts. This type of design freedom allows an engineer or industrial designer to improve functionality through increased complexity, which is not usually the case with traditional manufacturing methods. The result is an intricate, unique and lightweight product with a high level of strength.

There are fewer errors and the ability to identify and resolve problems before printing. To achieve a similar result with traditional methods would require additional steps such as cutting, milling, machining or forming. In other words, additive technologies make it possible to create geometries that were previously impossible to produce.

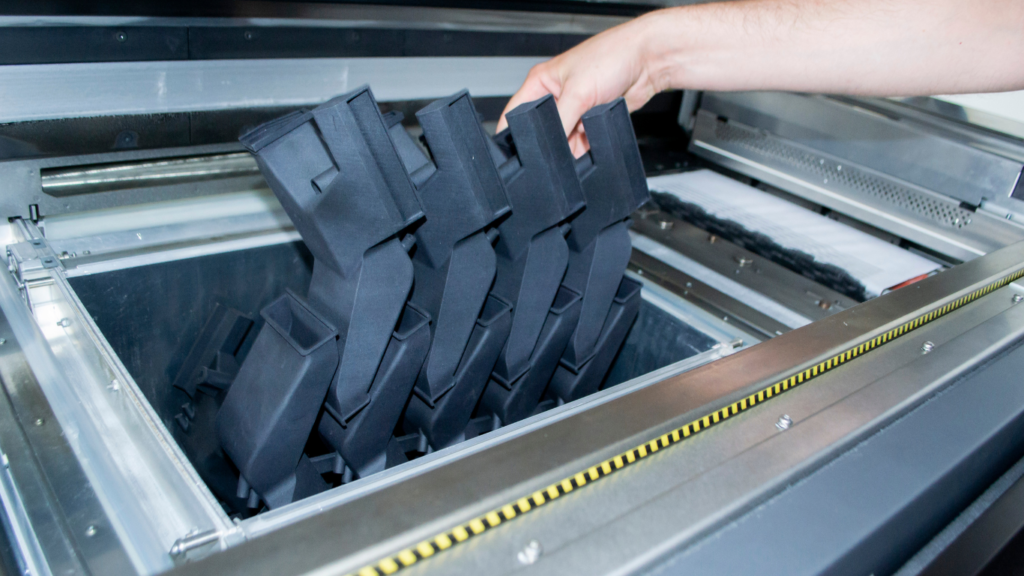

While additive technologies have primarly been used for prototyping, software and hardware materials have been maturing to produce production-quality end-use parts, a process known as direct digital manufacturing.

Now more than ever, development can advance with faster iterations of high-quality physical prototypes. Additive manufacturing can be applied to products in a wide range of industries, including medical, dental, biotech, aerospace, automotive, construction, industrial design, education, fashion, food and many more.

Additive manufacturing offers your project the freedom of a lightweight, low-cost, durable product whilst meeting the demands of a complex design. Some of the additional benefits of additive manufacturing are:

- Enables the creation of unique parts

- Allows customers to make rapid changes to prototypes during production, enabling a dynamic, design-driven manufacturing process

- Reducing lead times, as a single component can be produced without the need for additional assembly steps

- Produce finished components thanks to advances in both process and materials

- Produce less waste than traditional subtractive processes

- Enable low-volume production runs, reducing investment in time and costs

- Offer unlimited applications suitable for a wide range of industries

Prototyping & manufacturing technologies

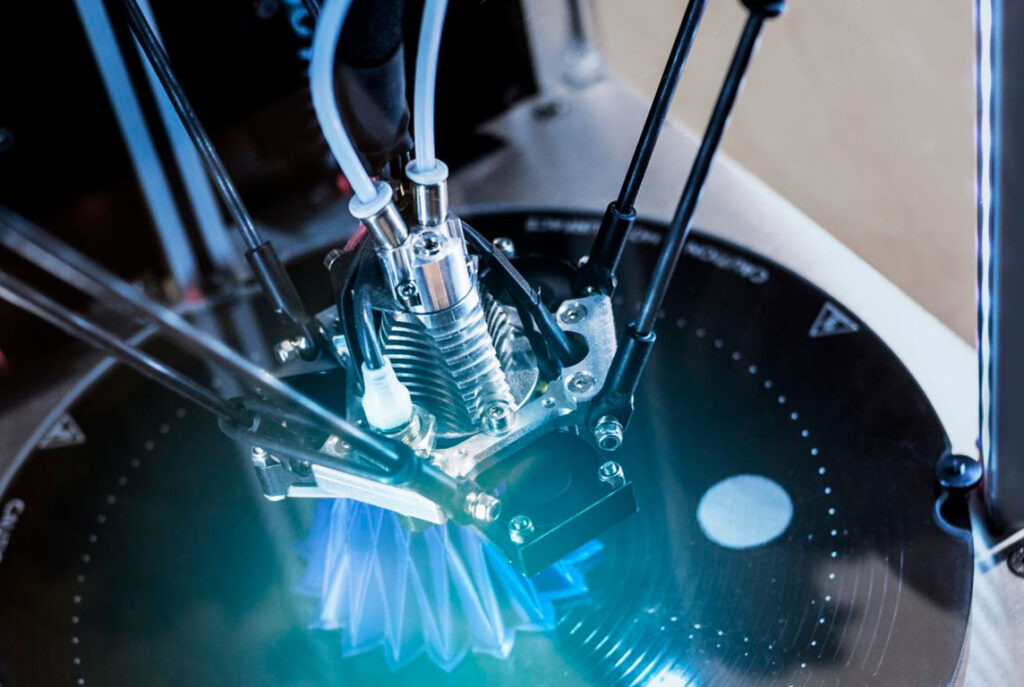

Explore our range of cutting-edge services, from Stereolithography (SLA) to Digital Light Processing (DLP), Fused Deposition Modeling (FDM)… Elevate your projects with precision and versatility.

How the Ryoga engineering team can help you in the development of your product:

Ryoga’s experts recognise the value of collaboration between design and manufacturing early in the product development process. We can be involved at the various stages of your process where you need us most, whether for a single unit installation or for high volume production. Below are examples of how our diverse group of engineers, designers and builders can help you take your project from definition to production:

Reverse engineering & 3D scanning

If we have existing parts, we have the technology and capacity to perform a 3D scan of them, either to reproduce them with the same morphology or to redesign them according to your needs.

Definition

Every project has unique design and manufacturing challenges. Come to Ryoga Engineering with your concept and we will work with you to better define your technical requirements. We will provide you with a logical path to prototyping without losing sight of the appropriate final manufacturing processes.

Rapid design & prototyping

We’ll use our in-house manufacturing resources and our network of approved suppliers to develop 3D CAD concepts and quickly deliver concept prototypes for early-stage validation. We have direct access to industry-leading additive technologies, so your project can be developed in record time.

Sophisticated design & prototyping

Our engineers and designers can help you translate concepts into detailed 3D CAD, resulting in refined prototypes with integrated aesthetics and function.

Our latests posts

We cater to a diverse range of industries, including medical, consumer electronics, automotive, aerospace, industrial, sports, and more.

Additive manufacturing, or 3D printing, builds objects layer by layer from a digital model, allowing for greater design freedom and complexity compared to subtractive methods like milling or machining.

Absolutely! Whether you need rapid prototyping or high-volume production, our team is equipped to handle your project from concept to completion using advanced additive manufacturing technologies.

Frequently asked questions

Explore our FAQs for answers to common queries about our services, technologies, and processes. Can’t find what you’re looking for? Don’t hesitate to reach out to us directly – we’re here to help with any questions or concerns you may have, no matter how unique.

Get in touch with us

Don’t hesitate to reach out to us at Ryoga Engineering! Whether you’re intrigued by our advanced 3D printing technologies or have questions about how additive manufacturing can benefit your project, we’re here to help. Contact us today to explore the possibilities and embark on a journey of innovation together. Your ideas, inquiries, and ambitions are the fuel for our collaboration. Let’s connect and turn your vision into reality!