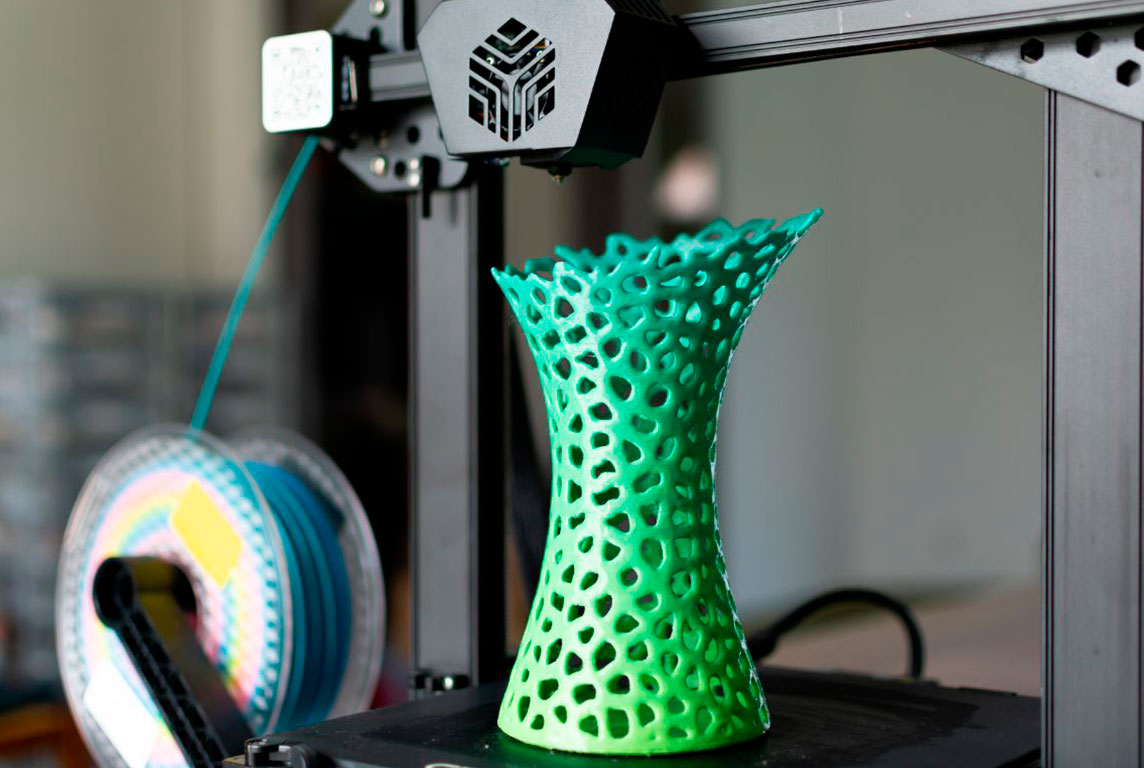

FDM (Fused Deposition Modelling)

- Dual independent extruder printer

- Allows to print multi-material high resolution multi-material resolution parts in a simple and and efficient way

- Uses thermoplastics at the production production level, so that the parts parts have mechanical, thermal and mechanical, thermal and chemical incomparable.

- Allows printing of high-resolution high resolution multi-material parts,as well as additive and semi-technical and semi-technical materials.

FDM - Materials

PLA

PLA Tough

TPU

Nylon

ABS

PET-G

ULTEM 1010

ULTEM 9085

ABS M30

Nylon 12

ASA

ABS

PC

TPU

CPE

CPE+

PC

PP

PV

MAX. VOLUME: : 406x355x406mm

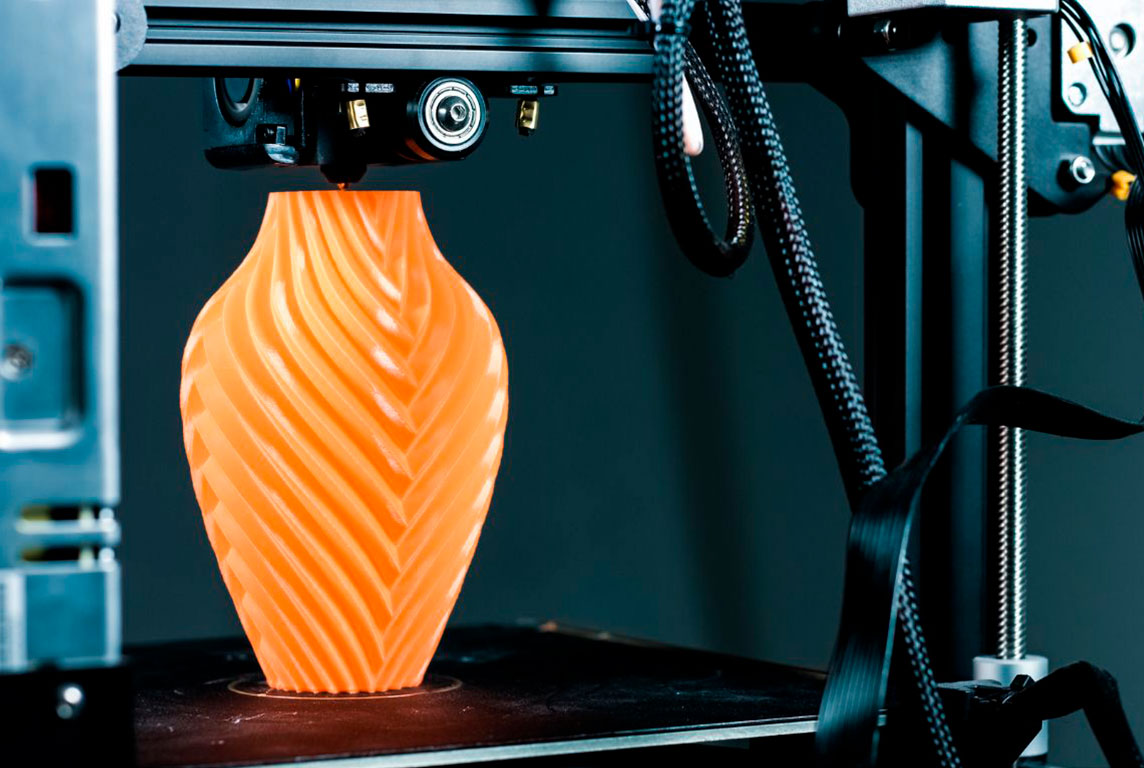

FDM is an additive manufacturing process that builds parts layer by layer using thermoplastic filament. A heated nozzle melts the filament, which is then deposited in precise patterns to create the desired shape.

FDM offers cost-effective production, fast turnaround times, and the ability to create robust parts with various thermoplastic materials. It's particularly suitable for rapid prototyping, functional testing, and low-volume manufacturing.

FDM supports a wide range of thermoplastics, including ABS, PLA, PETG, and nylon, each offering unique properties such as strength, flexibility, and heat resistance. This versatility allows for the production of parts tailored to specific application requirements.

Frequently Asked

Question

Welcome to our FAQs section, where we address common questions and provide insightful answers about our services and technologies. Explore this resource to find solutions to queries about our additive manufacturing processes, materials, capabilities, and more.

Get in touch

with us

Don’t hesitate to reach out to us at Ryoga Engineering! Whether you’re intrigued by our advanced 3D printing technologies or have questions about how additive manufacturing can benefit your project, we’re here to help. Contact us today to explore the possibilities and embark on a journey of innovation together. Your ideas, inquiries, and ambitions are the fuel for our collaboration. Let’s connect and turn your vision into reality!