SLA - Materials

Castable Wax

High Temp

Black Resin

Castable Wax Resin

Durable Resin

Elastic Resin

Grey Resin

Dental Mode Resin

High Temp Resin

White Resin

Tough Resin

Clear Resin

Flexible Resin

MAX. VOLUME: : 145x145x175mm

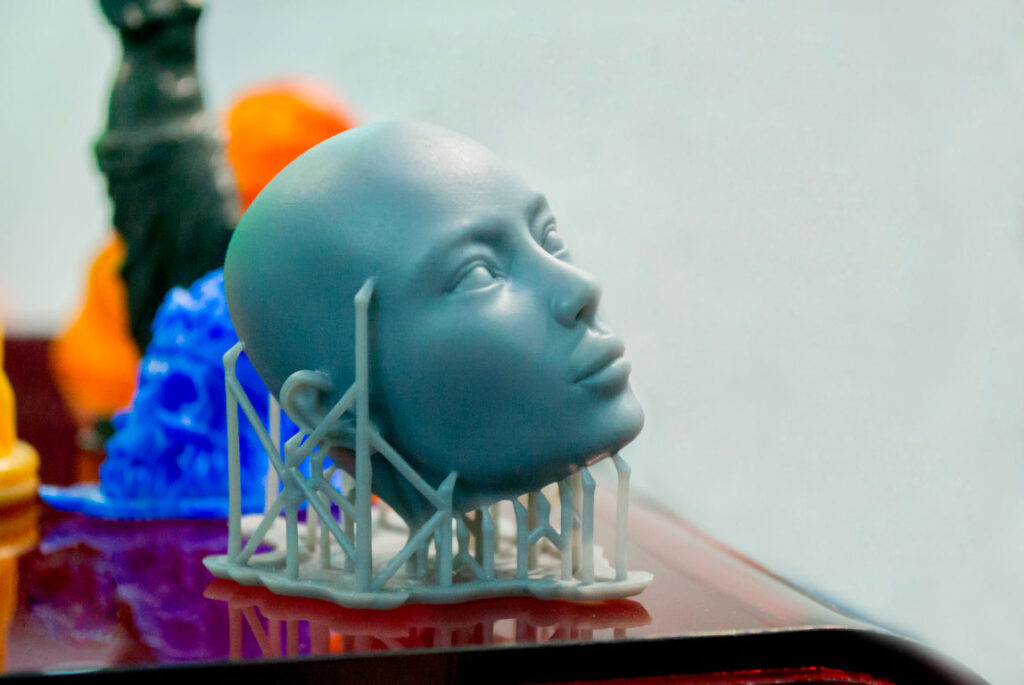

Stereolithography (SLA) is an additive manufacturing process that uses a UV laser to solidify layers of liquid photopolymer resin, creating highly detailed and accurate 3D models.

SLA technology offers high precision, smooth surface finish, and the ability to produce intricate geometries with fine details. It's ideal for rapid prototyping, functional testing, and creating master patterns for molding.

SLA supports a variety of photopolymer resins with different properties such as flexibility, transparency, and temperature resistance. These materials are suitable for a wide range of applications, including engineering prototypes, dental models, and jewelry prototypes.

Frequently Asked

Question

Welcome to our FAQs section, where we address common questions and provide insightful answers about our services and technologies. Explore this resource to find solutions to queries about our additive manufacturing processes, materials, capabilities, and more.

Get in touch

with us

Don’t hesitate to reach out to us at Ryoga Engineering! Whether you’re intrigued by our advanced 3D printing technologies or have questions about how additive manufacturing can benefit your project, we’re here to help. Contact us today to explore the possibilities and embark on a journey of innovation together. Your ideas, inquiries, and ambitions are the fuel for our collaboration. Let’s connect and turn your vision into reality!